Applications

Applications

Omni CleanAir's Leading Air Quality Solutions for High-Stakes Environments

Unhealthy air is a modern problem with far-reaching consequences. Omni CleanAir’s mission is to eliminate air-related illnesses in high-risk settings. Whether you’re working in construction with asbestos, mold, or lead exposure, or in manufacturing with hazards like silica dust, we have the solution.

In the age of pandemics, wildfires, and other natural disasters safety can’t be an afterthought. Hospitals need rigorous infection control, and indoor agriculture requires protection from airborne contaminants. When the stakes are high, consult the experts at Omni CleanAir.

Capturing Hazards During Abatement Projects

Prioritizing Worker Health on Construction Sites

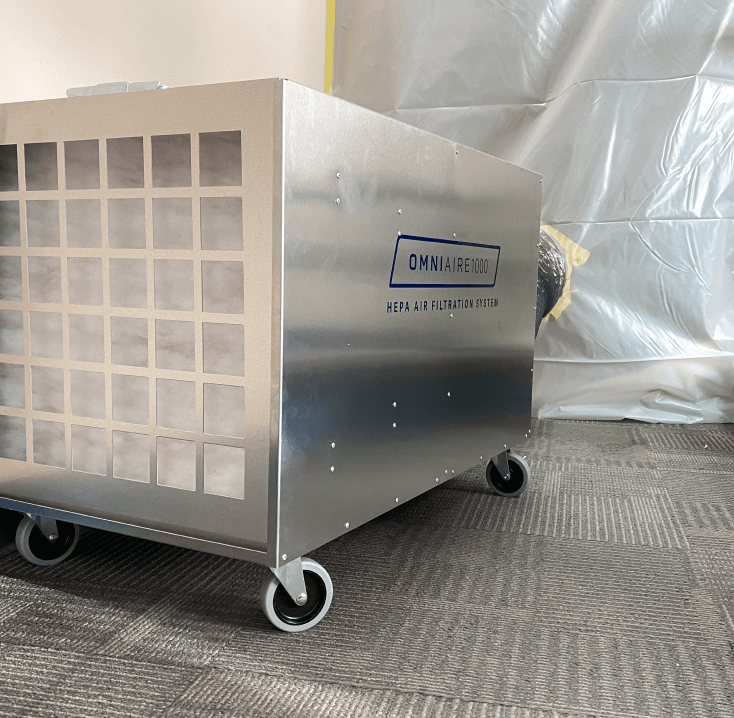

Ensuring a healthier and more productive work environment in the construction industry means prioritizing industrial-level air purifiers and scrubbers. These advanced systems capture and remove particulates such as sawdust and silica dust, and pollutants, meeting regulatory standards and safeguarding worker well-being. In hospital construction, Negative Air Machines are required to be compliant with ICRA guidelines. Responsible contractors and construction companies invest in air-cleaning technologies to minimize the dispersion of unhealthy pollutants on a job site.

Addressing Infection Control

Navigating within critical, often hostile environments reveals a host of challenges in preserving air quality and ensuring safety. Across domains as diverse as hospitals, laboratories, and nuclear facilities, these challenges are formidable. The risk of cross-contamination becomes an ever-present concern in laboratories, while the protection of sensitive equipment and the meticulous observance of stringent nuclear safety standards demand strict procedures. In times of crisis-based emergency responses and biohazard cleanups, the pressing need to restrict the displacement of harmful agents calls for rigorous measures. Within these situations, the role of OmniAire Negative Air Machines & Air Scrubbers and OmniClean Commercial/Medical Air Purifiers provide effective solutions for achieving compliance and mitigating risks.

Reducing Threats Related to Disaster Response

During disaster response, people often face critical challenges related to environmental and health risks in the aftermath of various catastrophic events. Airborne contaminants such as dust, mold spores, and hazardous particles pose significant threats to indoor air quality, particularly during fire cleanup, flood recovery, and other disaster scenarios. Additionally, the presence of excess moisture after floods can lead to mold growth, further jeopardizing the safety of indoor spaces. Amid search and rescue operations, emergency shelters, and healthcare facilities, the pressing need for good air quality and safer environments emerges as a core issue. It is in addressing these specific challenges that OmniAire Negative Air Machines & Air Scrubbers and OmniClean Commercial/Medical Air Purifiers become invaluable resources, contributing to the overall improvement of air quality, the creation of safer spaces, and the success of effective disaster recovery efforts.

Safety & Product Quality in Manufacturing

Manufacturing involves the transformation of raw materials into finished products, and air quality is an important consideration both for keeping workers safe and maintaining high product quality. In some cases, the process itself demands high levels of air quality to, for example, ensure surface finish and paint quality. In other cases, there are processes that produce large quantities of very dangerous airborne materials, like silica dust in countertop manufacturing, where workers must wear PPE and air filtration devices are required. In many cases, employers are required by worker health and safety regulations (OSHA) to provide clean, breathable air. In manufacturing, negative air machines and air scrubbers play a crucial role in controlling dust, particles, and contaminants generated during manufacturing processes. OmniAire Negative Air Machines & Air Scrubbers offer the flexibility to address the wide range of air quality challenges found in Manufacturing environments.

Importance of Indoor Air Quality to Healthy Buildings

Healthy buildings deliver improved indoor air quality for the health and safety of occupants. In the United States and most other regions of the world, indoor air quality fails to meet even the most basic, minimum regulatory standards. Indoor air is sub-par due to inadequate ventilation rates, outdoor air pollution from smog, wildfire smoke and industrial and automotive exhaust fumes, airborne contagions, off-gassing paints and other dangerous building materials, allergens including dust, tobacco smoke, and pollen. Healthcare facilities, schools, commercial buildings, communal living spaces and many other public spaces are in need of increased ventilation and filtration solutions. OmniClean Commercial/Medical Air Purifiers provide a broad range of medical-grade HEPA filtration solutions suited to the needs of a diverse set of environments.

Eliminating Contaminants in Indoor Agriculture

The ideal environment for a successful indoor grow operation demands air purity at the same levels found in food processing and medical facilities. Challenges in this indoor growing environment include controlling mildew and mold spores, avoiding cross-contamination and pollination, reducing odors and VOCs and minimizing other bio-contaminants to protect a high value crop. Operators face a complicated set of regulations and testing requirements that makes compliance mission critical. The agriculture-focused portfolio of AgriAir® Surface and Air Purifiers and Sanitizers helps maintain good air quality by removing contaminants and odors and proactively treating the air with ionized hydrogen peroxide.

With a legacy spanning over 30 years, Omni CleanAir has consistently been at the forefront of air quality solutions.

With a laser focus on high-stakes environments containing some of the most dangerous contaminants found, our array of Negative Air Machines, Air Scrubbers, Commercial Air Purifiers, and Differential Pressure Monitors have become industry benchmarks, applicable in areas such as Abatement, Infection Control, Disaster Response, Manufacturing, Commercial Buildings, and Indoor Agriculture.