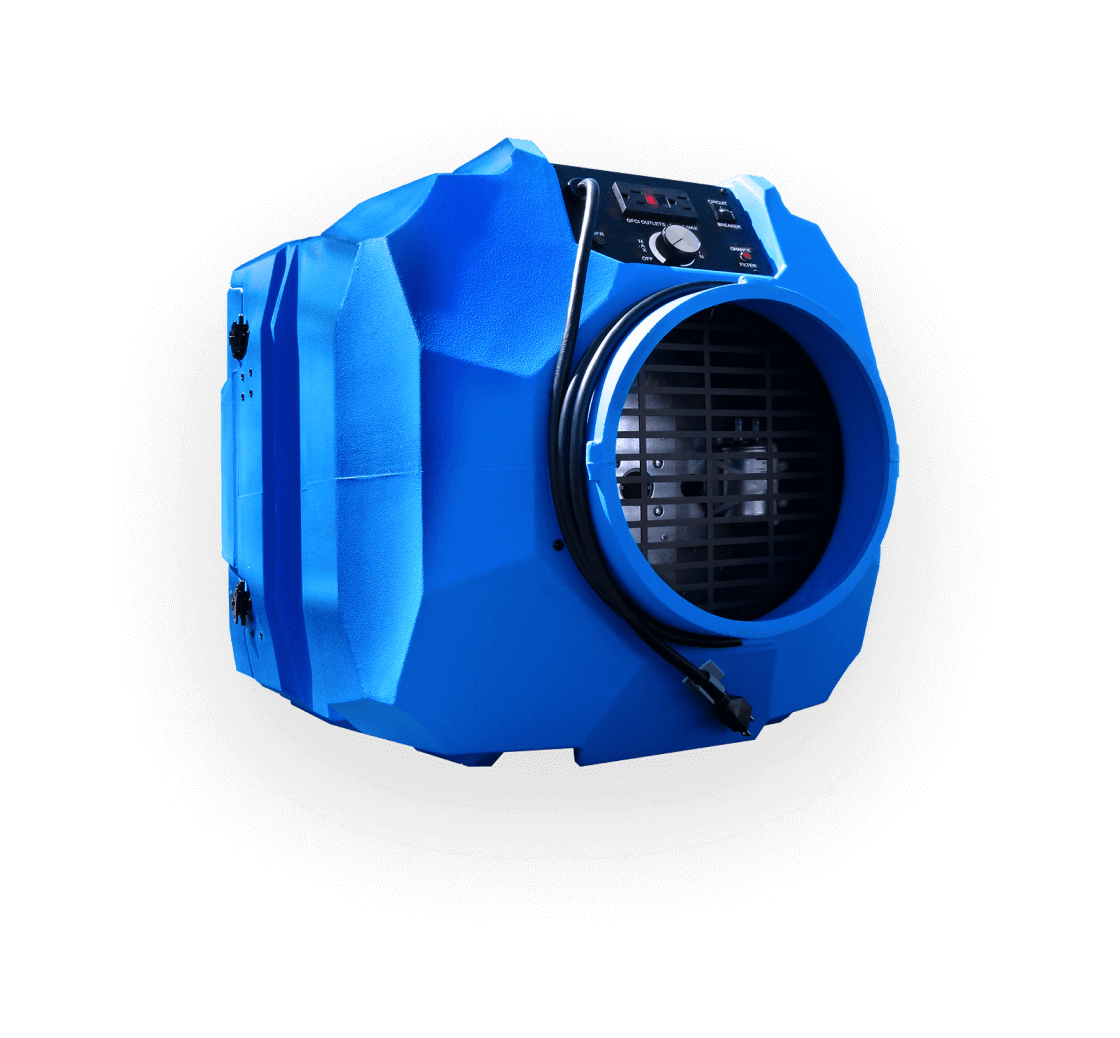

Experience medical-grade air purification and versatile air pressure control with the OmniAire 600 Series Negative Air Machines and Air Scrubbers. Compact and portable, these powerhouse HEPA filtration units are ideal for diverse applications including confined space work, restoration and abatement projects, medical facility construction, and more.

The OmniAire 600 Series is the preferred choice for cleaning contaminated air in tight spaces. Powerful HEPA filtration in a compact design, these machines can be deployed in both positive and negative pressure applications. The OA600 Series offers flexibility in construction with either durable rotomolded plastic or aircraft-grade aluminum housings. Variable speed controls provide precision CFM performance for any job.