CFM Calculator for Airflow Optimization

Begin by clearly defining the project’s nature and the specific contaminants you need to address.

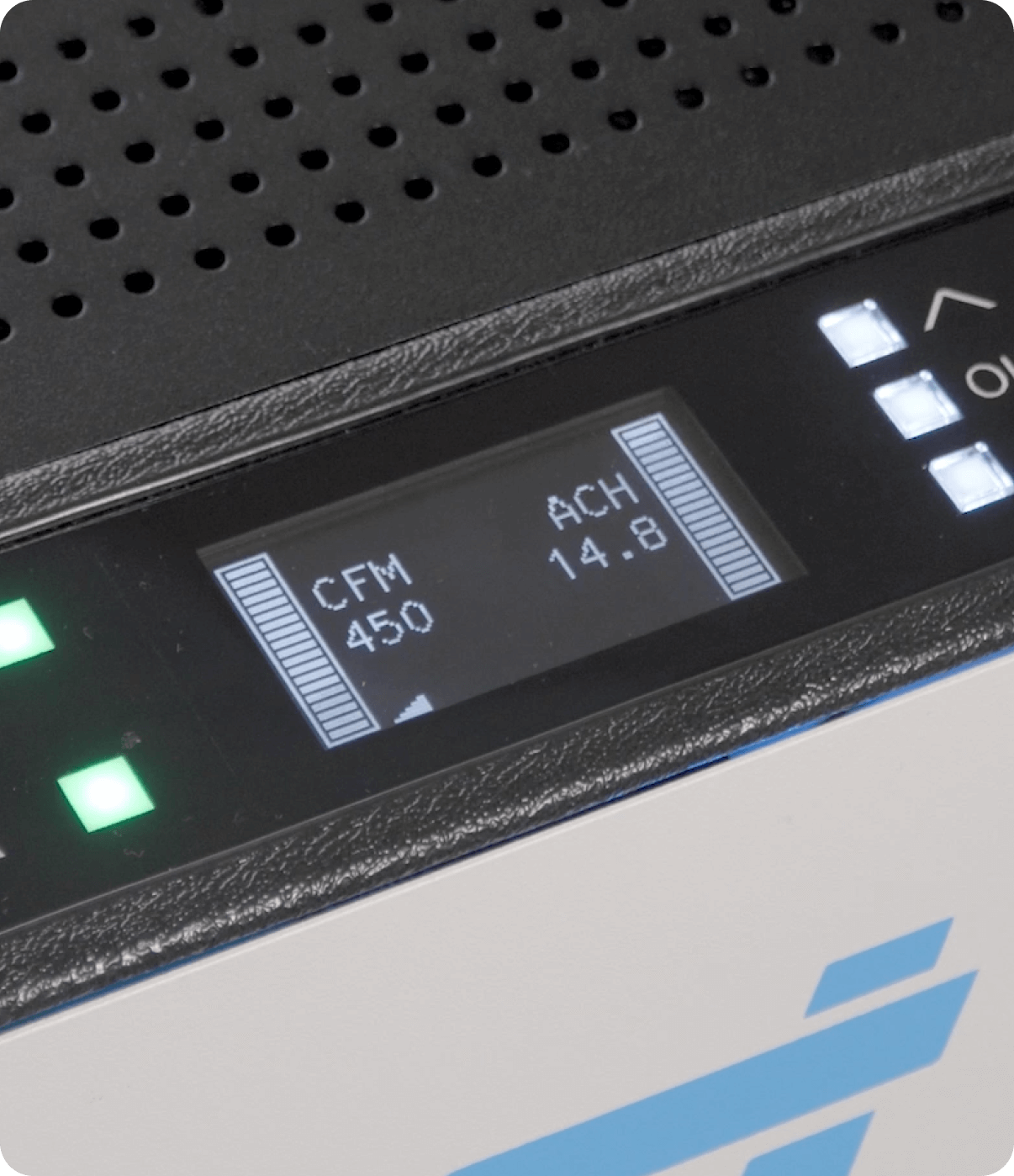

Calculate the required Air Changes per Hour (ACH) based on the size of the containment area and contamination levels, and then match it with the Cubic Feet per Minute (CFM) or Cubic Meters per Minute (CMM) rating of a Negative Air Machine.

Negative Air Machines with higher velocity ratings are generally more adept at handling larger volumes of air.

Assess the machine’s filtration efficiency, ensuring it features a High-Efficiency Particulate Air (HEPA) filter and potentially activated carbon filters for comprehensive contaminant removal.

To determine optimal air changes per hour or ACH follow these steps:

Select the appropriate units of measurement.

Enter the dimensions of your containment area into the calculator and hit calculate.

Review the results below, based on your input.

Refer to the provided list of models at the bottom of the page.

Let us know if you have any questions or need assistance.

SAE Airflow Calculator

Fill in your room details below.

Metric Airflow Calculator

Fill in your room details below.

OmniCleanAir Recommended Solutions:

Match your results to the products below.

Help Center

FAQs

An air scrubber, also known as an air purifier or air cleaner, is a device used to improve indoor air quality by removing various contaminants, such as dust, particles, odors, chemicals, and pollutants, from the air. Air scrubbers are commonly used in commercial, industrial, and healthcare settings to create a healthier environment. These devices work by employing various methods to capture or neutralize airborne contaminants. Some key functions of air scrubbers include:

- Filtration: Many air scrubbers use filters, such as HEPA (High-Efficiency Particulate Air) filters, to physically capture particles and airborne microorganisms. HEPA filters are highly efficient at trapping even very small particles.

- Activated Carbon: Air scrubbers can incorporate activated carbon filters to adsorb (the process of particles adhering to a substrate such as carbon) and neutralize odors, gases, and volatile organic compounds (VOCs). Activated carbon granules have a large surface area that can adsorb a wide range of chemicals.

- UVGI (Ultraviolet Germicidal Irradiation): technology is used in some air scrubbers to inactivate microorganisms like bacteria and viruses. It can be particularly useful in healthcare settings and places where infection control is crucial.

Both negative and positive air pressure systems rely on carefully designed ventilation systems and air filtration to achieve their respective goals.

- Negative air pressure is maintained in a room or zone when the air pressure inside the space is lower than that in the surrounding area. Used to keep contaminants contained within a specific area, Negative Air Pressure is often used in environments where the goal is to protect people or spaces from potentially harmful substances.

- Positive air pressure is maintained when the air pressure inside a room or zone is higher than that in the surrounding areas. Used to keep contaminants out of a controlled space, Positive Air Pressure is commonly employed in environments where maintaining a clean and controlled atmosphere is critical, such as in manufacturing processes or sensitive research settings.

Proper monitoring and maintenance of these systems are essential to ensure their effectiveness in maintaining the desired pressure differentials and air quality. The choice between negative and positive air pressure depends on the requirements of the space and the need to control the movement of particles and pathogens.

Indoor air quality (IAQ) refers to the condition of the air within buildings and structures, encompassing factors that impact occupants’ health and comfort. It involves the presence of pollutants like dust, VOCs, gases, and biological contaminants, all of which can have adverse effects on health. Adequate ventilation, humidity control, and temperature regulation are crucial for maintaining good IAQ.

Additionally, the infiltration of outdoor pollutants, such as automotive exhaust emissions and wildfire smoke, can further degrade indoor air quality, especially in urban or wildfire-prone areas. Monitoring and improving IAQ involves using air purifiers, proper ventilation, humidity management, and low-emission building materials. Prioritizing IAQ is vital for the well-being of occupants, especially those with respiratory conditions or sensitivities, and addressing both indoor and outdoor sources of pollution is essential for creating a healthier indoor environment.

Indoor air quality (IAQ) is evaluated by measuring critical variables that collectively determine the condition of indoor air. These variables include the concentration of airborne particles, such as PM1.0, PM2.5 and PM10, which are assessed using particle counters. Gas detectors are utilized to measure gases like carbon dioxide (CO2), carbon monoxide (CO), nitrogen dioxide (NO2), and volatile organic compounds (VOCs). Humidity and temperature sensors gauge the comfort and potential for mold growth, while radon detectors assess radon gas levels. Monitoring CO2 levels can indicate ventilation adequacy and relative humidity measurements are vital for ensuring proper moisture levels. These measurements, combined with the use of comprehensive air quality monitors and chemical analyses, when necessary, offer a comprehensive assessment of IAQ and guide efforts to maintain a healthy indoor environment.

Choosing an air purification machine is the most important step in improving indoor air quality. Here are some factors to consider when selecting the right air purifier for your needs:

- Determine the specific indoor air quality concerns you want to address. Is it particle, odor, or chemical removal? Does the air contain mold, viruses, or bacteria? What size room are you trying to clean? Identifying the parameters will help you choose an air purifier with the right features and capabilities.

- There are different types of air purifiers, including HEPA filters, activated carbon filters, UVGI purifiers, and PHI generators. Choose a type that targets your specific concerns.

- Calculate the size of the room or area where you intend to use the air purifier. Air purifiers are rated for specific room sizes, and airflow is measured in Cubic Feet per Minute, or CFM. Measure the room’s square footage plus height and convert it into cubic feet to choose a purifier with an appropriate CFM to achieve 4 to 6 air changes per hour.

- Choose the proper filter array for the air purifier. HEPA filters are highly effective at capturing small particles, while activated carbon filters are excellent for trapping odors and gases. Ensure that replacement filters are planned and accounted for in your operating costs.

- Consider noise levels, as some air purifiers can be noisy, which may be a concern if you plan to use them in reception areas, conference rooms, waiting rooms, or other quiet areas. Check the noise level specifications expressed in decibel (dB) ranges.

Once you’ve considered these factors, you can narrow down your options and make an informed decision. Keep in mind that using multiple air purifiers may be necessary for comprehensive indoor air quality management, especially in larger spaces.

To calculate the required CFM (Cubic Feet per Minute) for an air purification machine to be effective, you should:

- Measure the room’s length, width, and height to determine its volume in cubic feet.

- Decide on the desired air changes per hour (ACH) with typical ACH targets ranging from 4 for general indoor spaces, to 6 or higher for more sensitive environments, including Hospitals.

- To find the required CFM, use this formula or click on our CFM Calculator:

- Required CFM = (Room Volume x Target ACH) / 60.

- Example: A room with a volume of 6,000 cubic feet (a room measuring 30 feet by 20 feet with an 8-foot ceiling) aiming for 6 ACH would need an air purification machine with a minimum CFM rating of 600 CFM to achieve the desired air quality goals.

- Required CFM = (Room Volume x Target ACH) / 60.

- Ensure that the selected air purifier meets or exceeds the calculated CFM requirement, with a sealed HEPA filter – ensuring no air bypasses the HEPA filter.

Omni CleanAir HEPA Filters

Navigating HEPA manufacturers and thousands of HEPA filter variations is challenging, especially when deciphering specifications amid missing or inaccurate information.

In critical roles, relying on HEPA filters, confidence in performance is paramount. If you’re wondering what to look for when selecting a HEPA filter, take a look at our all-inclusive guide to help you understand not only the key four parameters that define HEPA performance, but also what HEPA filters map to the Omni CleanAir product solutions.